How does Industry Rust Removal Laser Cleaning Machine work?

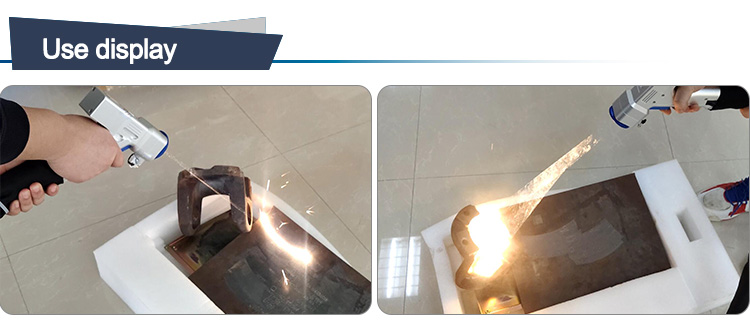

Industrial laser cleaning - or ablation - is the process of clearing away undesired material from a solid surface by irradiating it with a laser beam. By absorbing the energy of the laser beam, the targeted material is heated very quickly, making it evaporate or sublimate.

Features

1) Powerful, short pulses, fast moving laser pulses act on the surface of the target, producing tiny plasma ruptures, shock waves,thermal stress, etc., causing surface materials to sublimate and evaporate.

2) The focused laser beam is capable of accurately evaporating surface objects or dirt.

3) Fiber Laser cleaning is suitable for metal surfaces. The treated and optimized laser beam does not alter metal properties or damage those laser treated surfaces. The precisely tuned laser beam acts only on the coating, residual residue or oxide, and does not harm the underlying parent metal surface.

4) By adjusting other parameters, the laser beam is able to achieve the desired cleaning effect accurately and easily.

Comparing with traditional cleaning methods, laser cleaning has obvious advantages.

Fiber Laser Cleaning Machine Application

Whether the surface is metallic, plastic, ceramics, glass, stone or concrete, the results speak for themselves.

Metal surface derusting

Surface paint removal paint treatment

Surface without dirt, stains, dirt cleaning

Surface coating, coating removal

Oxide surface,Oil stain and contaminant cleaning

Welding surface / spray surface pretreatment

Stone figure surface dust & attachment cleaning.

Rubber/plastic/metal mold residue cleaning

Model | OV-QV1000/2000/1500 |

Laser Power | 1000W/2000W/1500W |

Laser source brand | Raycus/JPT/IPG |

Working mode | Continuous CW/modulation |

Working Distance | 150mm/ 250mm/ 500mm |

Cable Length | 10 Meters (Can be lengthened) |

Laser Wavelength | 1064μm |

Working Mode | Auto/ Manual |

Laser Gun weight | 0.5kg |

Power Supply | 220v/50Hz/ 2A or 380V/ 50Hz 2A |

Working Temperature | 5℃-45℃ |

Working Humidity | <90% |

Laser Class | IV |